Product Introduction

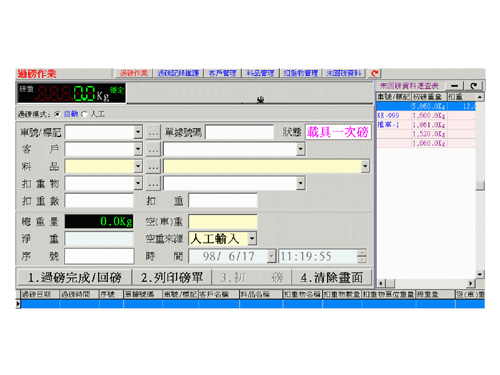

1. This system is designed for the weighing processing of small factory floor scales. Users can choose the weighing method according to their situation, which is distinguished as follows:

(a) Net weight weighing: When the item being weighed does not require the additional deduction of "deduction weight" or "carrier weight", it is weighed in this way. At this time, the weight obtained is the net weight of the item. This kind of weighing only needs to be done once.

(b) Weighing with miscellaneous items: When the items to be weighed need to deduct the "miscellaneous item weight", weigh them in this way. At this time, the net weight = weighing weight - miscellaneous item weight. There are two types of weight deductions: "fixed-weight weight deductions" and "variable-weight weight deductions". For fixed-weight weight deductions, the computer can automatically calculate the weight value by using the method of "unit weight" * "quantity". However, for variable-weight weight deductions, the user must input the weight value themselves to calculate the net weight value. This kind of weighing only needs to be weighed once.

(c) Weighing by vehicle: When users weigh items by pushing them with a trolley or other vehicle, the weighing shall be done in this way. At this point, the net weight = total weight - empty weight (vehicle weight). If the weight of the vehicle is known, it only needs to be weighed once. If the weight of the vehicle is not fixed, it needs to be weighed twice.

Note: "Vehicle weighing" and "weighing with a load" can be treated together. In this case, the net weight = total weight - empty weight (vehicle weight)- weight of the load.

2. The computer can be connected to one or two weight displays, and the weight can be obtained automatically without the need for manual input. And it can support the connection of weight displays from various brands. (The dual-pound function is optional.

After the weighing process is completed, the weighing slip can be automatically printed and this data can be stored. If the weight slip fails to print (such as paper jams), allow it to reprint the weight slip. In addition, in special circumstances, it is also possible to choose to store only the data without printing the weight slip.

After the weighing is completed, the computer automatically generates the weighing serial number. The serial number can be automatically reset to zero when changing years, months or days, or reset manually. It can also be specified that each weighing platform generates its own serial number or does not distinguish at all.

5. In the weighing process, for customers, materials, heavy objects, etc., by inputting codes or allowing users to directly select in the window through a selection window, it can avoid inputting Chinese characters. Moreover, the codes for customers, materials and heavy objects can be automatically numbered by the computer, and users can customize the format of the numbering.

6. It has a "Document Number" field, and users can flexibly use this field as needed. For example, you can enter "inbound order number" or "outbound order number", etc.

7. According to actual needs, the data from the previous weighing can be flexibly retained to speed up the weighing process. The fields that can flexibly retain the last weighing data include: vehicle number/mark document number delivered to the customer

weight deducted weight deducted number weight deducted

8. According to actual needs, it can be set whether individual weighing fields must input data to require operators to input the data accurately and maintain the availability of weighing data. (Except for the material which is a field that must be entered, other fields that can be set include: vehicle number/mark document number for the customer to load heavy items)

9. For weighing by vehicle push, the continuous weighing function can be performed: after the items are returned to the scale, the initial weighing operation can be immediately resumed (press the Enter key in the "Vehicle Number/Mark" field after the return is completed). At this time, the weight of this return is equal to the weight of the next initial weighing, which is convenient for handling the weighing of multiple items in a "batch loading and unloading" style.

10. The trolleys or other vehicles within the factory can be filed. Then, when the items pushed by these vehicles are weighed, the empty vehicle weight can be automatically deducted to accelerate the operation process.

11. Each weighing data is recorded with the source of its empty (vehicle) weight (on-site weighing, self-input, file data) to clarify whether the empty (vehicle) weight was obtained through weighing or other means.

12. All weight data are stored to one decimal place.

13. You can specify the starting time of a day's work (not midnight) by yourself, and when making reports, the computer will automatically handle the issue of data ownership across days.

14. It is possible to print detailed reports of weighing data for a certain day or a certain period of time.

15. According to customer classification, weighing statistics reports or detailed lists for a certain day or period can be printed.

16. Weighing statistics reports or detailed lists for a certain day or period can be printed by material classification.

17. All the "empty (vehicle) weights" of the detailed reports are merged into the "deducted Weights" column to simplify the reports. However, the "deducted weight" on the weight slip is merged into the "Empty (Vehicle) Weight" column, as the standard weight slip does not have a deducted weight column.

18. All statistical reports can be printed as text reports, bar charts or proportion charts. Daily and monthly statistical reports can also be printed as trend charts. (Printing graphic reports is an optional function.

19. The function of converting text-based statistical reports into Excel files (requires the installation of Microsoft Excel for normal conversion). This function is an optional feature.

20. All reports can be selected with the following filtering conditions: single or all customers, single or all materials, single or all weighing platforms. And the content at the top and bottom of the report page can be customized.

21. Reports and weight receipts can be separately set to be printed by different printers. The software can simulate page sizing and paper tearing. There is no limit to the brand of the weight receipt printer (as long as it is a dot matrix type), nor is there a limit to the length of the weight receipt paper.

22. The password must be verified as correct before entering this system for operation. And all functions should be able to set usage permissions for convenient management.

23. If the weighing operation cannot be processed by the computer due to computer failure or other factors, authorized users are allowed to input the weighing data manually after the fact.

24. If the stored weighing data is incorrect, authorized users are allowed to modify it. Moreover, if the weighing record is modified or deleted, the computer will automatically save the data before the change and provide a function for querying the change of the weighing record to facilitate management. When making modifications or deletions, you can enter the reasons for the changes for future verification.

25. Supports network operations and can be used in conjunction with local area networks, allowing multiple computers to access the same database simultaneously. Moreover, in the event of a network disconnection, if the database is not stored on the weighing computer, the weighing computer can still operate normally in single-machine mode. Once the network returns to normal, it will automatically upload the weighing data from the single-machine operation to the host to maintain the integrity of the data.

26. It provides an automatic database backup function (on an annual basis) to minimize the risk of data loss and allows for the query of past weighing data by year.

27. Any combination of conditions can be used to filter or query data, and commonly used query conditions can be memorized.

28. It provides a combined data export function. Users can customize the fields to be exported and their order according to their needs, and choose to export them to reports, Excel files, text (.txt) files or dBASE(.dbf) files. The exported files can also be sent to MIS personnel via email.

29. The daily weighing data can be converted into Excel files, text (.txt) files or dBASE (.dbf) files at regular intervals and sent to the designated network location or FTP Server, or automatically sent to MIS personnel via email. This function is an optional feature.

30. Important error messages, warning messages and prompt messages generated during daily operations can be saved on file for future analysis of the causes of errors and understanding of the situations encountered during daily operations.

31. It provides a function for storing weighing logs. When each vehicle is weighed, the weighing status can be immediately saved to retain the most complete weighing transaction record, facilitating the review of the actual weighing situation.

32. It has anti-fraud functions. When the original weighbridge data is deleted or the empty vehicle weight in the vehicle file is modified, a warning message record will be generated for future verification.

33. It provides an automatic shift handover function. When the set time (multiple time points can be set) arrives, the operator will be automatically cancelled, so that the management personnel can accurately grasp the shift handover status of each weigher. (Optional Function

34. The company's letterhead can be printed on the blank space above the standard weight slip.

400-019-1051

400-019-1051 400-019-1051

400-019-1051