400-019-1051

400-019-1051 400-019-1051

400-019-1051

Bulk material scale/ RECOMMENDED PRODUCT

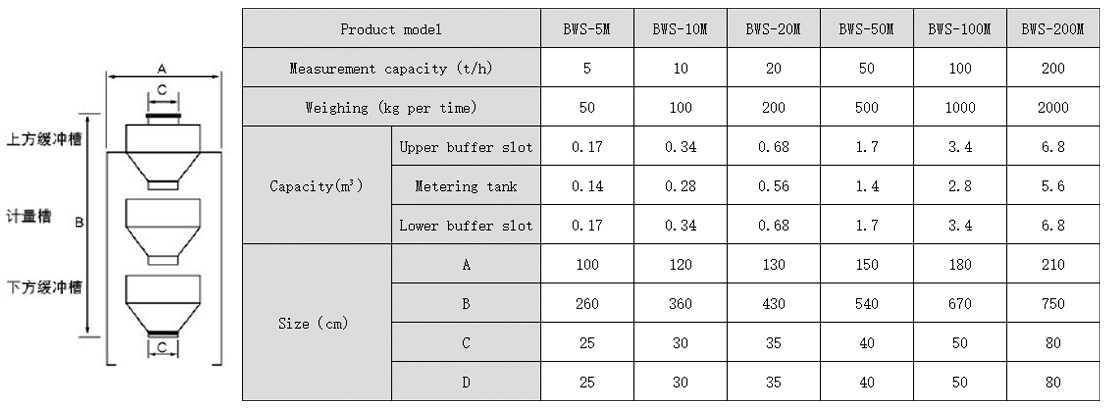

During the transportation of bulk materials, it is often required to measure the weight of the materials without interrupting the material flow. This weight value can be used within enterprises to settle inventory, monitor raw material consumption and control the production process, and can serve as the basis for trade settlement. In order to effectively solve the measurement problem of bulk materials, our company, based on its practical experience and professional technology in the field of bulk material handling, specializes in manufacturing the BWS type electronic bulk material scale. It is a bucket scale for automatically weighing bulk materials. It can divide a batch of bulk materials into several discontinuous loads, measure the weight of each load in sequence, and then accumulate these load values. Obtain the total material value. Because it uses static measurement instead of dynamic measurement, it is not affected by factors such as equipment vibration and material unevenness during the material conveying process, which greatly improves the measurement accuracy. It can meet various weighing function requirements such as receiving, transporting, distributing and quantitative loading of bulk materials, and has an extremely high cost performance among similar products. This product is suitable for application in various operation processes such as the receiving and dispatching measurement of small and medium-sized grain depots, intermediate measurement in the grain processing industry, intermediate measurement in the beer brewing industry, raw material receiving measurement in the feed processing industry, and raw material receiving and intermediate measurement in the oil processing industry.

Focus on quality

Various specifications

Factory direct sales

Customization supported

Hassle-free After-sales Service