400-019-1051

400-019-1051 400-019-1051

400-019-1051

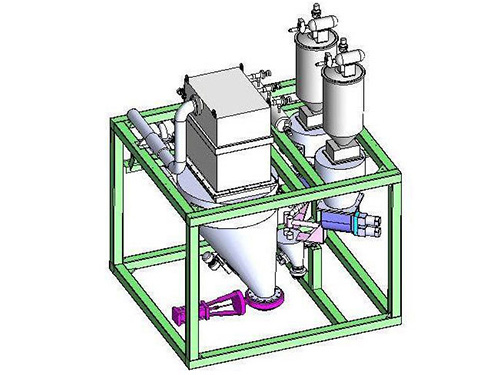

Large material batching system (Batch type)/ RECOMMENDED PRODUCT

Focus on quality

Various specifications

Factory direct sales

Customization supported

Hassle-free After-sales Service

The system occupies a small space. Compared with other traditional auxiliary machines, it can reduce the space occupation by 50%, thereby saving 50% of the construction cost.

The raw material area is separated from the production area. The combination of vacuum conveying of raw materials and weighing with scales reduces equipment investment by 30%, saves labor costs for handling raw materials, and there is no dust pollution.

Sharing raw material barrels for multiple lines can save equipment investment costs.

Design the scale according to the unique needs of customers to ensure better applicability.

By using wind pressure to change the material flow rate, multi-stage feeding and over-limit protection parameter setting, high-precision measurement is ensured.

| Model | ABS-100DA-6 | ABS-200DA-6 | ABS-500DA-6 |

| Ingredient type | Big ingredient ingredients | ||

| Product type | Powder metering machine (Air conveying metering type) | ||

| Raw material weighing (Kg) | 100 | 200 | 500 |

| Number of scales (units) | 1 | 1 | 1 |

| Quantity (types) of raw materials | 6 | 6 | 6 |

| Formula quantity (groups) | 30 | 30 | 30 |