400-019-1051

400-019-1051 400-019-1051

400-019-1051

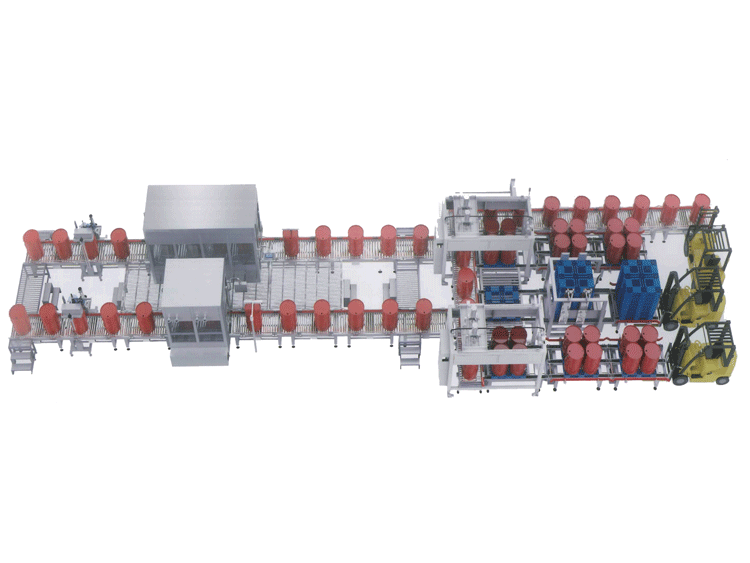

Fully automatic production line/ RECOMMENDED PRODUCT

Focus on quality

Various specifications

Factory direct sales

Customization supported

Hassle-free After-sales Service

| Product project | Components | Filling capacity | Applicable barrel type | Number of filling heads | Production capacity | Filling accuracy | Working power supply | Gas source pressure | Applicable materials |

| Technical parameters | Manual bucket placement/automatic bucket feeding/automatic hole finding/automatic cap opening/automatic filling/automatic cap locking/automatic cap arrangement/automatic outer cap pressing/automatic labeling/automatic palletizing/automatic stack supply/automatic film sewing/forklift bucket unloading | 200L | 200L round iron drum/plastic drum (open) | 2 | 60 to 80 barrels per hour | ±0.1% | AC220V/380V,50Hz | 0.4-0.6MPa | Flowable liquid products such as resins, coatings and chemicals |